Applications of plasma technology

Ecology

Safe plasma pyrolysis and gasification of various waste :

• Safe treatment and disposal of biomedical wastes

• Plasma treatment of organic waste that contains chlorine

• Plasma treatment and disposal of toxic and chemical waste using plasma reactors, including industrial waste

• Plasma treatment of toxic fly ash originating in incinerators and power plants to inert slag

• Safe treatment solution for scrap tires with hydrocarbon fuel production

Energy

Waste to Energy the plasma process :

• Various organic waste can be converted to synthesis gas and liquid fuel in the plasma reactor with high efficiency

• Synthesis gas and liquid fuel can be used in a gas turbine or a combined cycle generator to production electrical and thermal energy with efficiency of 30-90%

Construction Materials Technologies

Production of high temperature heat insulating ultra and super thin microfibers from molten mass or solid minerals :

• State of the art technology and implementation enable the production of ultra and super thin mineral fibbers from hard-to-melt minerals (basalt, quartz, etc). The resulting fibbers are effective heat-insulators and are used to manufacture mats, tiles, cardboard and other products used in construction, aviation and marine, metallurgy and energetic

• Production of heat-resistant hollow ceramic microspheres and macro-spheres manufactured from aluminum oxide and zirconium oxide (materials that are widely used as lightweight filling materials for composite materials, sound and heat insulating materials)

• Plasma finishing of construction materials surfaces: plasma vitrification of concrete, silicates and other construction materials where the two are used as a basis. Depth: 0.1 to 0.8mm

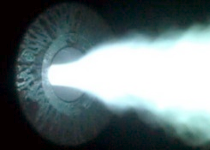

Plasma Processing of Materials

Basic Applications of Plasma Processing of Materials :

• Active carbon regeneration

• Plasma plating

A process has been developed for the plating of crankshafts of heavy-duty trucks and tractors using wear-resistant materials. Processed parts’ life is 80-100% longer than the guaranteed period of new crankshafts

• Extra-fine plating of metallic and non-metallic materials: 0.01-0.1mm

Metallic and inter-metal plating of various materials, without prior heating: copper plating of carbon, nichrome plating of glass, copper plating of stainless steel, zinc plating of quartz, nickel-based intermetallic compound plating of copper

• Thermal processing of materials in the form of powder for various technological processes

• Production of materials in the form of powder

• Spheroidization and other types of plasma-chemical agglomeration of powders

• Industrial processing of hard-to-melt materials

We offer ecologically clean plasma technology